Melt Flow Indexer warehouse|melt flow index chart : commercial Melt flow testing is a test method used to determine the flow properties of thermoplastic materials. The test measures how much material flows through a standardized die while subjected to a .

Stealing the Diamond. Stealing the Diamond är den tredje delen av den populära Henry Stickmin-spelserien. Hjälp Henry Stickmin att bryta sig in i ett museum och utföra ett diamantröv. Välj en av de riskabla metoderna för att få diamanten och se konsekvenserna av dina handlingar. Detta peka-och-klicka-äventyr sätter dig i en juveltjuvs .

{plog:ftitle_list}

O empresário Narciso Mendes, que chegou no Acre há cerc.

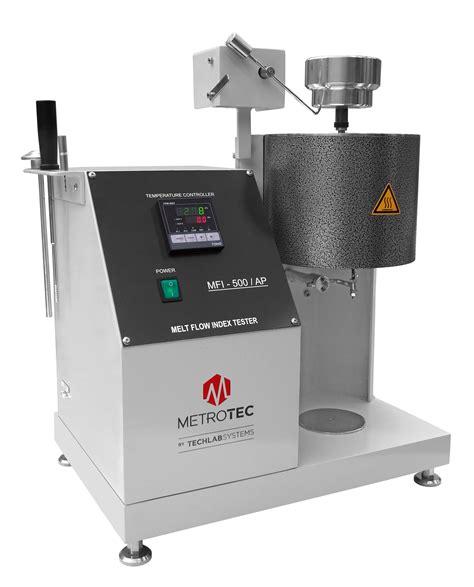

melt flow indexer price

Polymer manufacturers deliver high quality to meet ever changing end-use requirements. Dynisco melt flow indexers are recognized for testing the physical properties of polymers. Our .Dynisco melt flow indexers are used to evaluate the processability of materials. .ASTM/ISO Method B Test Using the Dynisco LMI5500 Melt Flow Indexer. .ASTM/ISO Method A/B Test Using the Dynisco LMI5500 Melt Flow Indexer. .

Dynisco-Viatran. Lot 3615, Jalan SM 6/8 32040 Seri Manjung, Perak, Malaysia .Melt flow testing is a test method used to determine the flow properties of thermoplastic materials. The test measures how much material flows through a standardized die while subjected to a .Melt Flow Indexers. Tinius Olsen is proud to introduce our latest evolution of melt indexer to meet almost every need. This new model, the MP1200, meets, and surpasses, all the requirements of Procedure A and Procedures B, C and D of .

A Melt Flow Tester is normally used to check the consistency of incoming materials by measuring the Melt Flow Rate (MFR/MVR) of samples. For a more accurate investigation on material properties, the next step is to determine the Flow Rate Ratio (FRR), which can be more efficiently obtained with multi-weight tests.The Davenport MFI-9 melt flow indexer is used to determine the melt flow rate of a polymer by extruding it in a molten state through a calibrated die using a reference weight. The MFI-9 is a competitively priced product, which achieves high accuracy, repeatability and reproducibility of results. The instrumentThe modular GÖTTFERT mi-2 series melt flow indexer allows users to upgrade from a manual operated entry-level unit to a semi-automatic machine. ASTM D1238; ISO 1133; ASTM D3364; GÖTTFERT product overview Melt Flow .ASTM/ISO Method A/B Test Using the Dynisco LMI5500 Melt Flow Indexer. Dynisco melt flow indexers are used to evaluate the processability of materials. Get quick and accurate measurements of melt flow characteristics to determine material quality, lot to lot consistency, and ensure what you are buying is what you need.

The MFi5 is a compact instrument that allows rapid inspection of the melt mass flow rate of plastics to Method A, Method B and Method C. It is especially designed for different needs, from simple Incoming Material Acceptance to Process Control checks. The manually operated MFi5 tests plastics quickly and reliably thanks to the pre-set methods.Melt Flow Index Tester: MFi7 The MFi7 is a melt flow index tester for a growing volume of Procedure A, Procedure B and Procedure C tests. Designed to increase production speed, it offers high level of accuracy and shorter cycle times overcoming manually powered limits thanks to fatigue-free motorized cleaning and automatic material compacting and purging.The Melt Flow Indexer – MFI model SNR is a rigid constructed table apparatus using the latest touch screen controller technology with a very intuitive software. It has audible prompts at the correct time and results calculated and displayed at the end of the test. With the displacement transducer MVR testing can be performed.

Using the latest on-board microprocessor technology, the Ray-Ran MFR300 is the most accurate and easy to use melt flow indexer available. Advanced melt flow indexer software The MFR300 comes Wi-Fi enabled for easy wireless results transfer the latest edition of Ray-Ran`s Techni-Test software platform which is supplied as standard.Melt Flow Index testing, crucial for assessing plastic resin flow properties, requires strict adherence to ASTM D1238 or ISO1133 standards for accuracy. . The melt indexer needs to be in good working order; The machine must have been calibrated by a certified metrologist, checking temperature, physical dimensions, and distance and time .

BS EN ISO 1133-1:2011: Plastics.Determination of the melt mass-flow rate (MFR) and the melt volume-flow rate (MVR) of thermoplastics; ASTM D1238: Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer BS2782: Methods of testing plastics.Introduction

Melt flow indexer is used to determine the melt mass flow rate (MFR) of thermoplastic resins. The melt flow index tester from Wewon Environmental Chambers Co., Ltd. is suitable for engineering plastics such as polycarbonate, nylon, fluoroplastic and polyarene with high melting temperature.

The Melt Flow Indexer is designed to determine the melt mass-flow rate (MFR) and melt volume flow rate (MVR) of thermoplastic as well as test the high melt temperature such as PC, Fluor plastics, and nylon, but also PE, PP, POM, PS, ABS resin which has low melt temperature. This testing machine is designed to perform tests according to AS, ASTM and ISO standards.

the Melt Flow Indexer than from commercial processing equipment. These are Die Swell and Draw Down. 6 MFI 10 User Manual 1.3 DIE SWELL Die Swell or swelling ratio, is an arithmetic ratio between the diameter of the cooled extrudate at ambient temperature and the diameter of the die. This is an important factor for processes such asA flow rate test is a measure of a polymer's mass flow rate (grams extruded in 10 minutes) using a particular orifice under specified conditions of temperature and load. Machines that determine flow rate are generally called Melt Indexers. Test methods by ISO, DIN, ASTM andModular Melt Flow Indexer series mi2.x. Details. MI-3. Melt Flow Indexer MI-3. Details. mi40. Melt Flow Indexer mi40. Details. mi40 visco. Melt Flow Indexer mi40 visco. Details. MI-Robo. Fully Automatic Melt-Index-Robot. Details. Capillary Rheometer. RHEOGRAPH 20. High-Pressure Capillary Rheometer RHEOGRAPH 20.Melt flow indexer – MFI 450 Series. The user-friendly Melt flow indexer – MFI 450 series combines high accuracy and precision essential for quality control and R&D. Easy operation with colour touch screen control for fully automatic .

Melt Flow Indexers are used in a broad range of applications, from quality assurance in raw material production to final product testing in manufacturing. By determining the melting rate of a polymer, these devices .

melt flow index tester price

from the Melt Flow Indexer than from commercial processing equipment. These are Die Swell and Draw Down. 6 MFI 9 User Manual 1.3 DIE SWELL Die Swell or swelling ratio, is an arithmetic ratio between the diameter of the cooled extrudate at ambient temperature and the diameter of the die. This is an important factor for processes such asMelt Flow Indexer Standards ISO 1133, ASTM D1238, ASTM D3364, BS 2782, DIN 53735, JIS K7210 Description Our melt flow indexer is a highly precise instrument designed for the measurement of melt flow rate (MFR)/(MI) or melt volume rate (MVR) in quality control and research applications. The

Measuring MFI: The Role of the Melt Flow Indexer. Specialized laboratory equipment by the name of a melt flow indexer precisely measures MFI. This instrument meticulously maintains a specified temperature range while also employing a consistent weight load to extrude the material through a capillary. One such example of such sophisticated .MFI Measuring device. The Melt Flow Index (MFI) is a measure of the ease of flow of the melt of a thermoplastic polymer.It is defined as the mass of polymer, in grams, flowing in ten minutes through a capillary of a specific diameter and length by a pressure applied via prescribed alternative gravimetric weights for alternative prescribed temperatures. [1] [2] Polymer .A flow rate test is a measure of a polymer’s mass flow rate (grams extruded in 10 minutes) using an orifice under specified conditions of temperature and load. Machines that determine flow rate are generally called Melt Indexers or Extrusion Plastometers . Test methods by ISO, DIN, ASTM and others specify heat chamber andThe MFR200 melt flow indexer offers a more automated procedure compared to the MFR100, vastly improving results accuracy for “method A” testing. The test procedure is very simple to conduct. Molten Polymer is extruded through a closely controlled orifice (die) from the apparatus using pre-set conditions for temperature and pressure .

The GÖTTFERT MI-3 offers the possibility to perform single weight measurements according to ISO 1133 as well as ASTM D1238 (Procedure A-B-C) and ASTM D3364 in quality and incoming goods inspection.The Melt Flow Indexer is a dead-weight extrusion plastometer. It consists of a thermostatically controlled melting chamber (the barrel) in which the polymer under test is heated and from which it is extruded through a standard die under standard conditions of load, which is, of course, made up of the combined weights of the extrusion piston and the loose weight both of which are .Testing is performed using a melt low indexer in accordance to either ASTM D1238 (Melt Flow Rates of Thermoplastics by Extrusion Plastometer) or ISO 1133 (Determination of the Melt Mass-Flow Rate and Melt Volume Flow Rate of Thermoplastics). The instrument consists of a temperature-controlled cylindrical annulus through which a polymer melt is .

Melt Flow Index (MFI) คือการวัดความง่ายของวัสดุเทอร์โมพลาสติกที่สามารถไหลภายใต้ความดันและอุณหภูมิที่กำหนด เป็นตัวบ่งชี้ความหนืดและน้ำหนักโมเลกุลของ .

Portable dried fruits and vegetables Moisture Meter distribute

About Press Copyright Contact us Creators Advertise Develo.

Melt Flow Indexer warehouse|melt flow index chart